DIE CASTING

DIE CASTING

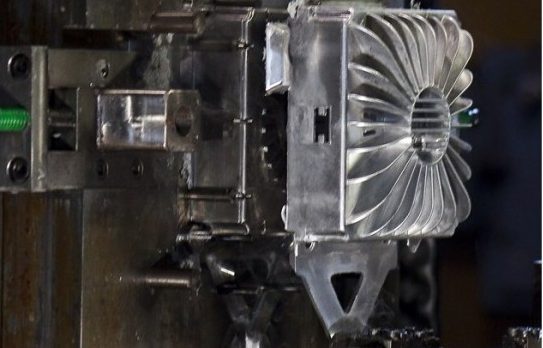

PMB di Bugatti makes use of fully automatic presses with robotic part removal, automatic lubricators, autoloaders and holding furnaces. The presses are equipped with water temperature controllers to ensure constant management of the mould temperature. The company can produce die-castings weighing from 10 g up to 5 kg, and in either small or large production batches.

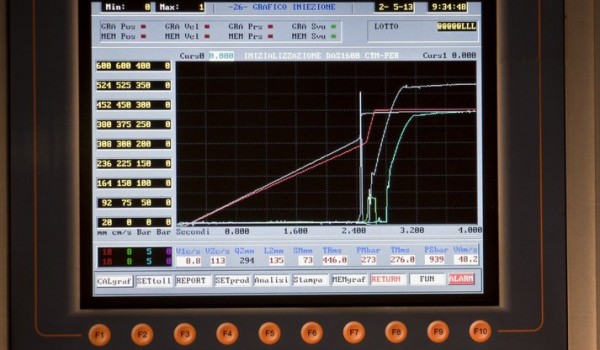

The aluminium die casting process is very complex and includes the treatment of the aluminium alloy, the melting, the management of the precise quantities of aluminium injected into the mould, the timing of the solidification process and lubrication of the mould. Continuous inspection throughout these phases enables us to obtain homogeneous production and high quality castings.